Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

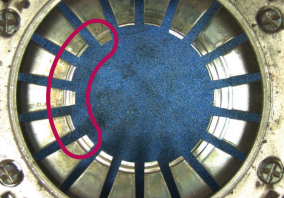

Clutch Diagnostics

Category

Tow Bars (14) Skid Plates (2) Wheel Spacers (2) Floor Mats (9) Seat Covers (4) Car Care (7) Accessory Lights (6) Work Lamps (4) Vehicle Badges (5) Bed Liners (1) Chrome & Stainless Trim (8) Roof Bars (2) Side Steps (3) Wheel Accessories (7) Wind Deflectors (10) Windscreen Protectors (7) Equipment & Tools (29) Performance (29) Gift Ideas (42) Manuals (8) Vouchers (3)

Engine Filters (126) Filter Kits (49) Cam Timing Belts (43) Engine Oil (15) Engine Fan Belts (46) Engine Electrical (79) Engine Seals (12) Starter Motors (14) Alternators (13) Glow Plugs (12) Cylinder Head (9) Engine Gaskets (44) Head Bolts (1) Engine Consumables (8) Engine Cooling (53) Engine Covers (17) Engine Manuals (8) Engine Sensors (25) Engine Turbo (18) Engine Hoses (15) Engine Sump Pan (7) Ignition (16) Spark Plugs (6) Engine Pulleys (36) Engine Mounts (18) Fuel System (72) Fuel Injectors (7) Fuel Pump (27) Fuses & Relays (13) Suction Control Valves (10) Additional Engine Items (34)

Service Kits (62) Filters (139) Cam Timing Belts (46) Fan Belts (42) Wiper Blades (36) Coolant / Antifreeze (5) Engine Oil (8) Ignition (16) Fluids & Oils (34) Glow Plugs (12) Grease (7) Plugs & Washers (25) Service Tools (16) Spark Plugs (6) Service Manuals (8) Service Electrical (69) Screen Wash (2) Fuel & Engine Additives (8) Consumables (36)

Coil Springs (28) Leaf Springs (22) Shock Absorbers (58) Suspension Kits (32) Lift Kits (12) Front Bushes (47) Rear Bushes (45) Drop Links (28) Ball Joints (13) Shackles & Pins (18) Anti-Roll Bar (62) Bump Stops (13) Lift Shackles (4) Fluids (1) Mounts (7) Wishbones (58) Torsion Bars (3) U Bolts (4) Active Height Control (33) Trailing Arms (7) Additional Suspension (52)

Brake Discs - Front (63) Brake Discs - Rear (26) Brake Pads - Front (30) Brake Pads - Rear (7) Brake Shoes (18) Brake Hoses (35) Brake Calipers (50) Brake Master Cylinders (18) Brake Backing Plates (37) Brake Consumables (2) Brake Drums (7) Brake Fitting Kits (33) Brake Hardware (51) Brake Hydraulics (16) Brake Kits (38) Brake Performance (13) Handbrake Cables (30) Brake Valves & Sensors (54) Wheel Cylinders (7) Additional Brakes (36) ABS System (46)

Chassis (2) Front Bumpers (26) Front Wings (8) Grilles & Surrounds (26) Rear Bumpers (7) Rear Corner Panels (2) Rear Window (3) Tailgates (9) Seat Belts (13) Interior (7) Aerials (11) Badges & Emblems (13) Bumper Brackets (14) Body Electrical (3) Door Sills (1) Doors & Hinges (10) Exterior (18) Floor Mats (9) Fuel Tank Parts (25) Door Handles (9) Lock Sets (2) Mirrors (64) Mud Flaps (43) Pedals & Rubbers (2) Rear Arch Panels (2) Seat Covers (4) Spare Wheel (13) Splash Guards (14) Steering Wheels (11) Tools and Equipment (20) Tow Bars (14) Wheel Arches (15) Wheels (4) Wind Deflectors (10) Window Motors (1) Wipers (44) Additional Body Parts (65) Skid Plate (2)

Track Rod Ends (35) Steering Bushes (7) Steering Dampers (3) Steering Idlers (4) Steering Boxes (2) Steering Racks (20) Steering Rods (5) Steering Knuckles (31) Ball Joints (15) Drag Links (2) Pitman Arms (2) Steering Pumps (12) Steering Consumables (8) Steering Wheels (15) Additional Steering (38) Seal Kits (10) Fluids & Oils (1) Steering Pipes (1) PAS Belts (1)

Front Ball Joints (14) Front Wheel Bearings (30) Free Wheeling Hubs (8) Front Differential (76) Front Axle Seals (44) Front Axle Bushes (47) Swivel Seal Kits (11) Front Studs (5) CV Boots (12) CV Joints (29) Driveshafts (27) Front Axle Consumables (14) Front Axle Kits (7) Front Axle Tools (4) Front Gaskets (7) Drop Links (12) Front Wishbone Arms (36) Oil & Greases (15) Stub Axle / Knuckle (36) Swivel Hub (22) Wheel Nut (10) Front Anti-Roll Bar (39) Additional Front Axle (43)

Rear Wheel Bearings (45) Rear Axle Seals (28) Rear Differential (93) Rear Wheel Studs (5) Rear Axle Bushes (38) Rear Axle Consumables (11) Rear ABS Ring (3) Oils and Greases (15) Rear Axle Kits (4) Rear Axle Tools (4) Rear Gaskets (5) Drop Links (16) Rear Wheel Cylinders (8) Retainer Collar (5) Wheel Nuts (10) Rear Anti-Roll Bar (31) Trailing Arms (2) Additional Rear Axle (30)

CV Joints & Boots (29) Driveshaft's (14) Prop Shafts & UJ's (29) Front Differential (71) Rear Differential (88) Clutch (73) Mounts & Hardware (39) Transmission Kits (3) Transmission Gaskets (1) Transmission Seals (17) Transmission Filters (14) Fluids & Oils (11) Speedo & Sensors (8) Transmission Guards (2) Tools & Equipment (7)

Car Care Products (7) Axle Stands (1) Fuel & Engine Additives (7) Filter Pliers (2) Battery Chargers (5) Axle Pullers (1) Bottle Jacks (1) Fluids & Oils (34) Fuses (3) Grease (4) Grease Gun Dispenser (2) Hub Spanners (1) Jack Handles (3) Jump Leads (1) Lubricants & Cleaners (5) Microfibre Cloths (1) Oil Drain Pan (1) Paper Towels & Wipes (1) Power Inverters (1) Ratchet Straps (1) Screwdriver Sets (1) Silicone Gasket Makers (1) Work Lamps (3) Tow Ropes (1) Tyre Gauge (1) Air Compressors (1) Pliers & Grippers (2) Disposable Gloves (1) Exhaust Paste (1) Snow Chains (1) Razor Scrapers (1) Screen Wash (1) Multimeters (1) Antifreeze & Coolant Testers (2) Spanners & Wrenches (5) Axle & Bearing Pullers (1) Spot Lamps (1) Wiper Blades (14)